Excelitas offers innovative UV curing solutions that provide leading manufacturers worldwide with the most advanced, simple-to-use and reliable UV curing technology. Our OmniCure® product line leverages our long-standing, proven industry expertise to deliver faster and more consistent UV curing results to ensure our customers capitalize on highest product quality and production efficiency savings across various applications. UV curing systems offer a high degree of adaptability and ease of integration with a comprehensive product portfolio ranging from precision UV spot curing to advanced LED UV area curing systems. Addressing the demands of a wide range of UV applications, our core UV curing technology is designed to meet the demands of assembly applications that can be easily integrated into automated and stand-alone manufacturing environments.

With an increasing demand for manufacturers to maximize productivity of their plants around the world, UV and UV LED curing has become an important assembly technique in the manufacturing assembly process, due to its’ rapid processing, on-demand cure, ease of automation, low energy requirements and solvent-free bonding.

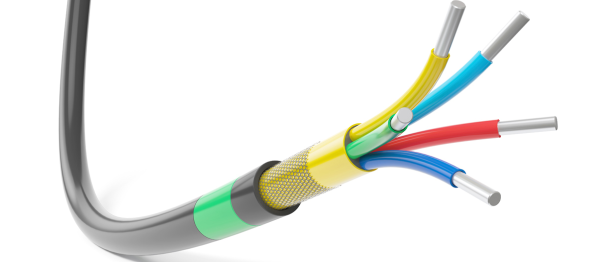

Cable assemblies are used in various industries to transmit electrical signals, power or data between devices. Typical cable assemblies consist of a set of wires combined into a single cable with a connector on at least one end and can range from simple wire harnesses to complex fiber optic cable assemblies.

An important bonding and assembly technique for medical device manufacturers is the use of UV curing adhesives due to their rapid processing, cure on-demand nature, ease of automation, lower energy requirements and solvent-free bonding.

Given the growing need for optical fiber cables, particularly in the telecommunications industry, manufacturers are continuously striving to enhance manufacturing efficiency while maintaining high standards of product quality and durability. The use of UV curing in optical fiber manufacturing provides numerous benefits, such as increased productivity, improved quality, and reduced waste, making it an attractive option for the industry.

Ultraviolet (UV) curing for wood coatings provides an effective and efficient alternative to traditional air, moisture, and thermal cured coatings. UV curing provides faster curing times, reduced energy consumption, and improved coating performance.